More Information

+91 120 452 0270

+91 120 452 0270

The landmark supreme court judgement in 1998 lead to Delhi/NCR switching to the use of Compressed Natural Gas or CNG in 2001 and Advantek Fuel Systems stepped into this market by not only identifying the problems faced by customers and users but also locating the best products/ components and solutions globally. A partial list of the components is given below

Manual cylinder valve without internal venting system

Parallel safeties (TPRD + PPRD) with pipe-away ports

Max working pressure: 260 bar

Working temperature: -40°C +85°C

Excess flow

Available in different thread sizes

Automatic cylinder valve with internal venting system (no gas tight housing required)

Max working pressure: 260 bar

Working temperature: -40°C +85°C

Thermal safety valve (PRD)

Burst disk available upon request

Manual security tap

Excess flow valve

Low absorption solenoid valve

Non-return valve avaible on request

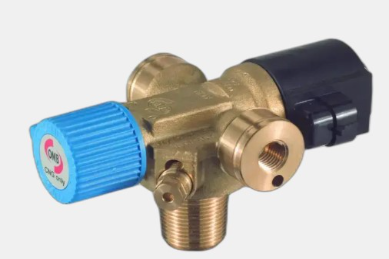

Filling charge valve NGV1

Max working pressure: 260 bar

Working temperature: -40°C +120°C

Manual safety tap – non-return valve – available in different thread connections

Special flow dynamic profile to avoid chattering noises during refueling

We are a technology and innovation-driven manufacturer for the automotive industry.

Copyright © 2025 www.advanteksystems.net All Rights Reserved. Design and Developed by Moxi Website Design